|

|

|

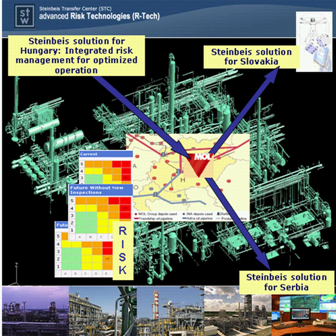

iRiS-Petro – integrated RISK MANAGEMENT SYSTEM

for Petrochemical plants

… integrates all relevant aspects of risks in petrochemical plants: RBI (Risk-based Inspection), RCM (Reliability Centered Maintenance), RCFA (Root Cause Failure Analysis) and HSE/HSSE (Health, Safety, Environment / Security), as a company-wide Intranet-Extranet-based platform. Includes risk monitoring, assessment and management as well a all levels staff involved (inspectors, operators, high-level management … )

|

RBM (Risk Based Management), RBI, RCM, RCFA, HSE and HSSE systems allow to include safety, environmental, business and reliability considerations into the decision making process and, thus, provide better targeting of resources and improving the results of the run-replace-repair decisions, as well as in the overall operation, safety, inspection and maintenance.

This is accomplished by considering the risks of possible undesirable events, the risk itself being expressed as the likelihood of the event (in a given scenario) multiplied by its probable consequences. Properly developed, implemented and used, the RBI, RCM, RCFA and HSE/HSSE systems help to significantly optimize plant key performance indicators (KPIs) and assure safe, economical and, hence, competitive operation.

|

|

| |

Steinbeis Advanced Risk Technologies Solution: The iRiS System

| |

| |

Steinbeis Advanced Risk Technologies Solution: The iRiS System

R-Tech proposes a RBI, RCM, RCFAand HSE/HSSE solution which is transparent and affordable. This solution is based on innovative, but recognized methodologies (USA, EU), widely used nowadays by the leading industrial companies, and use of the state-of-the-art methods and software tools (all Inter- /Intra-/ Extranet based).

The R-Tech solution provides support for the client to understand the major items needed to understand the RBI, RCM, RCFA and HSE and to apply these efficiently in the shortest possible time and, in most of the cases without having to change/replace the existing system(s)

|

|

| |

| | | |

| | | |

| |

Data/Asset Management:

|

Web-based overview of assets:

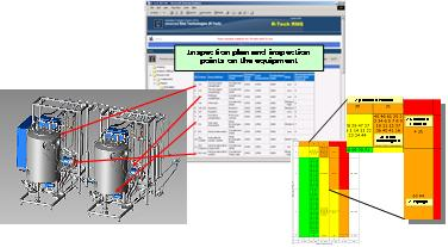

The software allows a web-based 3D view of the complete assets, starting from geographical distribution of the assets using predefined or GIS-based maps, towards true 2D or 3D models of the units, equipments and components.

The models are based on 2D drawings and 3D models from the existing CAD software.

Furthermore, the model allows the users to visually identify the equipment, components and locations where certain actions are performed.

The 3D model allows the users to get all the information needed (e.g., design information, performed analyses and inspections or planned ones) from one central point.

|

|

|

Data asset management:

Each piece of equipment in the system gets an appropriate data sheet for the given type of equipment that can hold all the information as required per standard specification (i.e. EN, API or ASME). This way, the engineering and asset knowledge is centralized in one single point. Directly from the data sheets, the information can be used at the same time as equipment specification (i.e. as replacement order).

|

|

|

Inspection record keeping:

For each piece of equipment, the appropriate records of performed inspections are kept. This way, it is traceable how the equipment state has changed trough time, and the early signs of problems can be easily identified and pinpointed. Furthermore, the inspection records can be directly used in RBI and RCM evaluations.

|

|

| |

| | | |

| | | |

| |

RBI Software

RBI software suite consists of the following software modules:

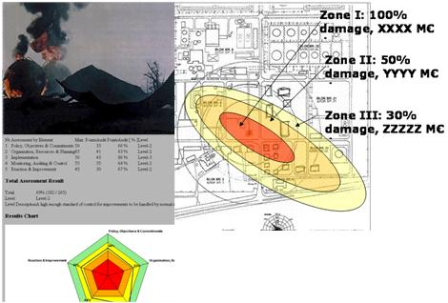

1. Management System Evaluation Module (MSEQ)

2. API 581 qualitative analysis (unit-based) system for unit-based approach (screening)

3. API 581 qualitative (component-based) – Level 1, semi-quantitative – Level 2 and quantitative

4. RIMAP-based assessment (option to be agreed with the end-user in each particular case)

|

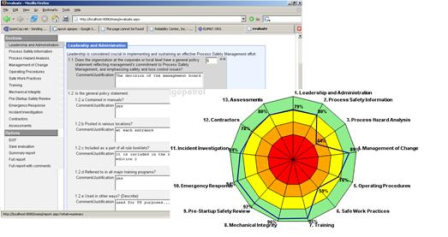

Management system evaluation module:

The MSEQ module is a questionnaire -based software for evaluation of Management Systems

made according to the APPENDIX D in API581 Base Resource Document

|

|

|

|

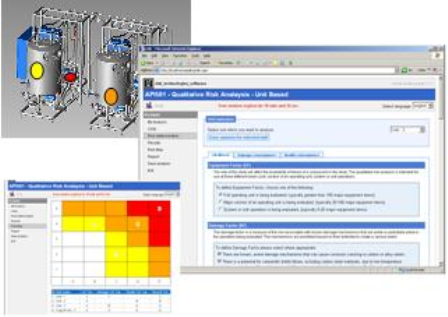

API 581 Qualitative Analysis System for Unit-based approach (screening) – QLTA:

R-Tech’s QLTA is based on the Workbook for Qualitative Risk Analysis given in Appendix A of the API581 Base Resource Document

QLTA is used to determine the Likelihood and Consequence Category for a given unit. Depending on the nature of the chemicals in a unit, the Consequence Category can be determined based on the flammable or toxic hazards for the unit. Flammable consequences are represented by the Damage Consequence Category, since the primary impact of a flammable event (fire or explosion) is to damage equipment. Toxic consequences fall under the Health Consequence Category, since their impact is usually limited to adverse health effects.

|

|

|

API 581 qualitative (component-based)

R-Tech API581 performs all the tasks necessary to determine the risk rank of the equipment and optimize the inspection plan for the equipment based on either qualitative approach (level 1), semi-quantitative approach (level 2) or quantitative approach (level 3).Level 1, semi-quantitative – level 2 and quantitative – level 3 analysis modules

R-Tech API581 performs all the tasks necessary to determine the risk rank of the equipment and optimize the inspection plan for the equipment based on either qualitative approach (level 1), semi-quantitative approach (level 2) or quantitative approach (level 3).

|

|

|

| |

| | | |

| | | |

| |

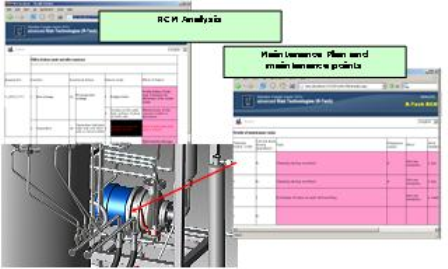

RCM (Reliability- Centered Maintenance module) covers all the aspects of the classical RCM approach, namely:

• Failure Mode and Effects Analysis (FMEA)

• Failure Classification (FCn)

• Failure Characteristics Analysis (FCA)

• Maintenance Strategy Selection (MSS)

Furthermore, the RCM application allows definition of equipment templates where all the data for all four phases of the analysis can be predefined, thus allowing fast and efficient data entry. The module is completely web-based and integrated with other elements of the system.

|

|

| |

| | | |

| | | |

| |

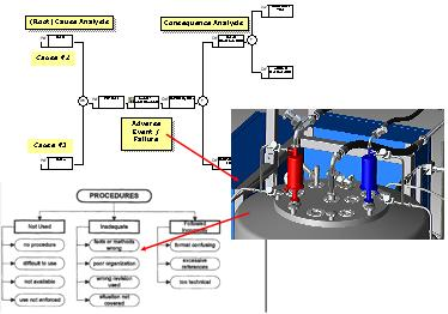

RCFA

The RCFA identifies most significant annual losses in an organization and supplies knowledge needed to identify the causes and possibly eliminate their recurrence in the plant in the future. RCFA relies on the comprehensive and effective data collection which is absolutely needed in order to manage the knowledge about failures and their (root) causes.

|

|

|

RCFA provides better insight both in what could go wrong and in what has gone wrong, using Basic Failure Modes & Effects Analysis (FMEA) and Opportunity Analysis. The end result is the analyses build a business case for which events are the best candidates for Root Cause Analysis based on the Return-On-Investment.

|

|

| |

| | | |

| | | |

| |

HSE/HSSE

HSE/HSSE is the concerned with protecting the safety, health, security, environment and welfare of the employees, organizations, and others affected by the work they undertake (such as customers, suppliers, and members of the public).

|

|

|

The HSE Module in iRiS-Power is based on current European and American standards in the area (i.e. Seveso II, ATEX, EPA require¬me¬nts), and is designed as a checklist against the requirements in order to identify critical equip¬ment and show com¬pliance with protect¬ion/mitigation measures.

|

|

| |

| | | |

| |

Implementation and maintenance of the system

| |

| |

Implementation and maintenance of the system

|

In order to simplify the data collection, data analysis and data presentation, as well as to reduce maintenance of the modules to the minimum, the following implementation scheme is foreseen:

• One central data/application server running MS SQL Server, Oracle or other database system for data collection, processing and presentation is foreseen

• One central web server, based on MS IIS, with support for MS .Net applications

• Web-browser based clients

• Reports and other data presentation tasks have web-based interface (Offline data presentation/browsing capabilities are also available)

• The implementation architecture provides the following benefits primarily in terms of reduced maintenance costs and reliability and simplicity of the maintenance/updating procedure:

o Data stored at one place and available for all authorized persons trough web-based interface

o Data collection is also done trough web-based interface, which allows interaction with data without any client software, apart from standard web browser

o The maintenance and further development of this part of the system is done on the central web- and data/applications servers only

|

|

| |

| | | |

| | | |

| |

Flow Chart of CEN Approved Risk Based Inspection & Maintenance (Enumerated on CWA 15740)

| |

| | | |

|

|

|

|

|

|